Annoying Noise from Treadmill?

The sound of a treadmill motor transmission is unavoidable. However, abnormal sound not only causes a poor user experience, but also indicates a possible quality problem with your running machine. This article discusses the quality of treadmill noise (abnormal sound) from the perspective of product design, manufacturing, quality control, and after-sales service.

Noises & Countermeasures

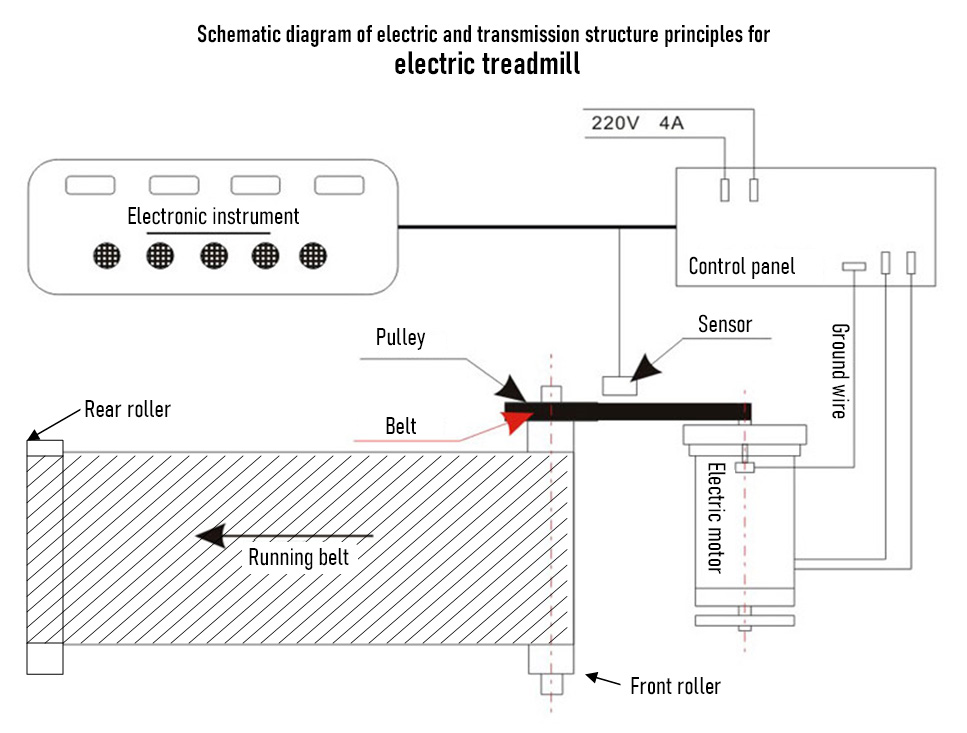

The running machine is mainly composed of three parts: the main frame structure, control system, and transmission system.The transmission system mainly includes: motor, belt, roller, running belt. According to our experience, most abnormal noise of treadmill results from machine structure and transmission system.Here, we explain those abnormal noise causes and countermeasures. The targeted readers may include fitness equipment sellers,distributors, importers, after-sales technician , quality controller, purchasing manager for China’s fitness equipment, and the designers for treadmills.

01. Design of structure

One of our clients developed a treadmill with a beautiful shape design, whose long stretch length caused the console at the tail to amplify the shaking amplitude and emit vibration sound during use. Although later, they adopted the material reinforcement and increase the buffer material as corrective action, but still they did not completely solve the vibration and abnormal sound problems caused by the improper structural design.

Countermeasures: It is too late, we have to say.If the design is finalized, the treadmills are already in mass production, it is hard to make any modification on structure. Either we just have to live with it, or we can figure out a way to optimize it a little bit,but not too much.

02. Rssonance&vibration

Although some people in the industry have mentioned resonance and the resulting sound problem, we can hardly say that the kind of vibration felt on a treadmill is mechanical resonance in the strict physics sense.

We don’t know whether the event of the collapse of the bridge caused by resonance caused by the uniform steps of the soldiers of Napoleon happened on the treadmill.

In fact, what we usually call “resonance” usually refers to the amplification effect of the shaking and vibration of the entire machine due to the configuration of the various transmission components of the treadmill. Therefore, vibration is the cause of noise, and the unreasonable configuration of transmission components is the cause of so-called “resonance”.

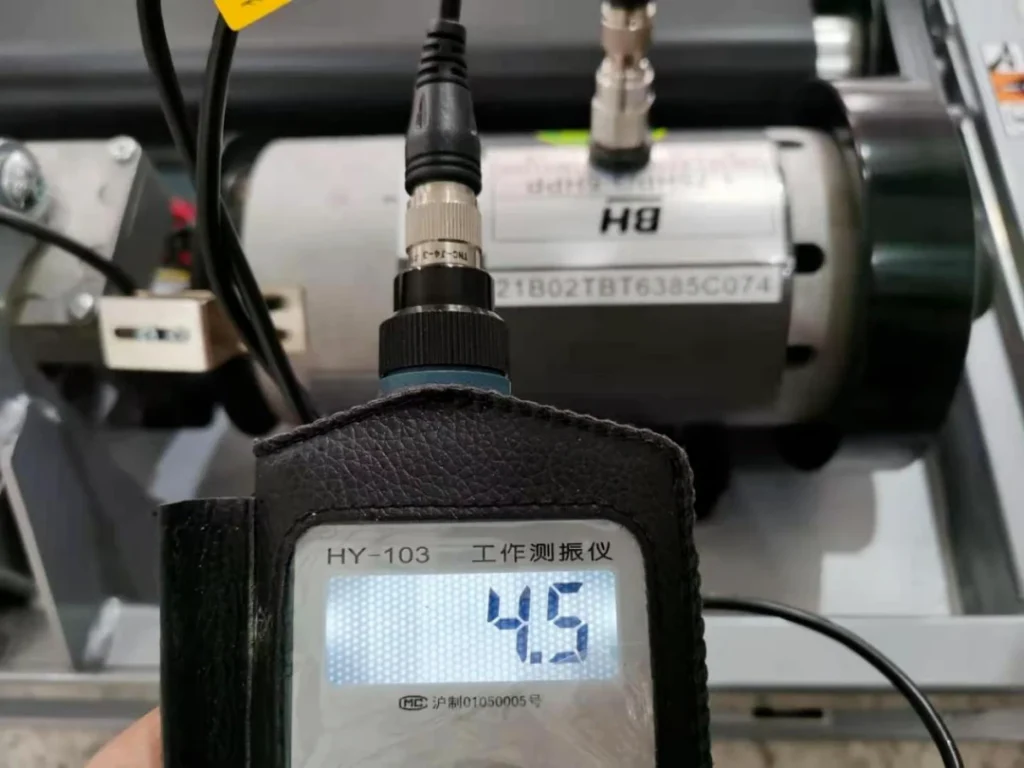

Some manufacturers also use a vibration tester to detect the vibration intensity of the treadmill motor during the production process. However, this value is only used as a guide and reference. At present, there is no unified judgment standard in treadmill manufacturing filed in China, and it relies more on the subjective feelings of quality inspectors who check the treadmills and motors.

Countermeasures: After eliminating the quality problem of the motor itself, you can try to adjust the fixed position of the motor, the tension of the belt, and the fit of the belt groove to see if the problem can be solved. The amplification of “resonance” or vibration effect is also related to the product structure design, but it is difficult to avoid it in the early design stage of the treadmill.

03. Narrow gap

Some transmission parts, such as the distance between the pulley of the drum and the lower cover of the motor or the distance between the running belt and the upper cover of the motor are too close, the movable parts interfere with other fixed parts during operation, causing abnormal frictional sound.

Countermeasure: Find out the position of interference in time and see if it is possible to adjust the assembly position and angle between them.

According to FQC criteria , usually at least a 2mm gap between the surrounding fixed parts of the transmission component must be ensured. In case of the material or area is prone to deformation, at least a reserved gap of 5mm or more must be ensured.

Countermeasures: Too small gap is sometimes because the product structure layout is restricted by limited space under motor cover, and only a small margin can be reserved. Of course, the more common cause of this problem is that the production assembly line workers did not performed in accordance with the standard operating procedures(SOP), therefore, the parts are not in its due positions.

04. Lifting motor

The clearance and loosening of the lifting motor and the oil cylinder fixing mechanism will also cause the sound of impact or friction. Sometimes it occurs during slope adjustment, and the dissonance disappears after the end of slope adjustment.

Countermeasures: Try adding some lubricating oil to the mechanical joint and see if it can be solved. If the noise cannot be solved. If not, then it must be solved from the modification of mechanical structure.

05. Running desk

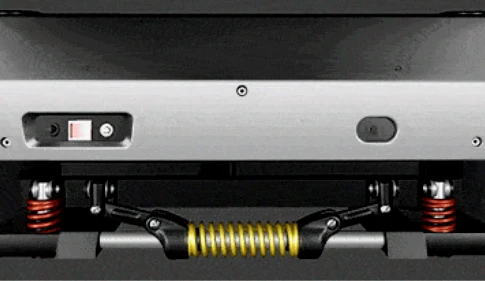

If the hardness of Running desk is too high, and with poor elasticity or time, damping device under the running desk did not work well, then the noise from treadmill desk would be higher than normal ones.

Countermeasures: If the specification of the component is inferior, the quality problem is doomed. To reduce the impacting and noise, you may buy one treadmill mat on Amazon store. Anyway, to improve the grade of your brand, it is necessary to use high-end running board and effective shock absorption device.

06. Motor problem

The motor is the “heart” of the treadmill, is also the power source of the treadmill transmission system. A bad quality motor will make an unusual whinnying noise.

Countermeasure: Nothing more to say about this. Simply get a new motor for replacement.

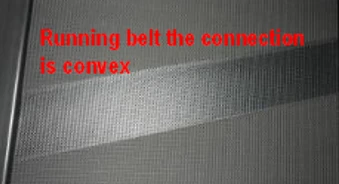

07. Joint of belt

A running belt with too thick joint will make a noticeable “thunk, thunk, thunk” sound when in contact with the roller. In addition, if the treadmill is idle for too long, the running belt is hardened, and the sound is more obvious at the beginning of operation. But after half an hour, it will be much smoother.

Countermeasures: Check the running belt after a period of time operation to see whether the noise disappears. If not, it is recommended to replace it with one new belt.

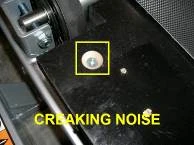

08. Loosen fastener

A loosen screw or fastener will make related parts movable and easily cause the impact and noise.

Countermeasures: Find the loosen fastener and fasten them tightly. Please make sure the screw threads not damaged during assembly.

09. Roller quality

The treadmill roller’s noise may result from the drop-off of balanced block or the defects of bearing system.

roller’s noise may result from the drop-off of balanced block or the defects of bearing system.

Countermeasure: Replace roller.

10. Uneven frame

There is gap between transportation wheel after assembly considering the floor is even. Then there is impacting noise during running.

Countermeasures: Adjust the foot pad knob (if any) to make up for the gap problem. It is worth noting that the serious main frame gap problem is caused during welding process and neglected by quality inspectors .

11. Belt lubrication

After a long time of use, the friction between running belt and running board increases due to insufficient lubrication, also emit dry friction sound.

For the knowledge of running belt, please refer to another article in our WECHAT official account: “Running belt for treadmill FAQ and configuration guidelines”.

Countermeasures: Treadmills need to add silicone oil regularly and timely, users can operate according to the instructions.

12. Interference

There is interference between belt and side-rail, between running desk and front roller, between motor cover and running belt… as long as there is a touching by moving part, there is a obvious sound.

Countermeasures: The user can adjust the alignment of running belt by using a hexagon wrench according to the instruction. For interference under the motor cover, it is better after-sales technician come to check.

Further discussion

At the product development stage, the designer should spend time talking to technical engineer, production manager, quality assurance department , after-sales support team and even key component suppliers. Some fitness equipment brands companies may sacrifice or ignore the mechanical rationality, structural stability, and product safety of running machines for the pursuit of appearance design aesthetics which brings difficulty and high cost to manufacturing processes, quality control, and after-sales service.

Quality management lends itself to more than just checking the appearance and function of a product when products are finished, it should cover the whole process , from concept design to product realization still customer service. Considering the actual situation of China’s fitness equipment manufacturing industry, the reliability and capability of fitness equipment quality can not reach the same level as that in electronics, automobile and other consumer product industries. Even though people recognizes that on-site quality control is essential to make a qualified product, the overall quality management system establishment is still lack behind of the market demands.

Comments (0)

No comments yet, be the first to comment!