Abstract

This article introduces the phenomenon of sliding on treadmill during running, and gives analysis on its causes V.S solutions. This content is for after-sales technician from fitness equipment distributors , quality controller in fitness equipment industry, and production manager at treadmill manufacturers.

Typical Phenomenon: Sliding

Running belt “sliding”on treadmill is one of the typical problems encountered during the running. If users find the phenomenon of slipping or feeling of an incoherent movement during exercise, they should stop running immediately to avoid the injury accident caused by falling down.

What should we do if the running belt of running machine slips?

Don’t worry, let’s find a way out. We are going to tell you how to determine the causes and the approach to solve the problem.

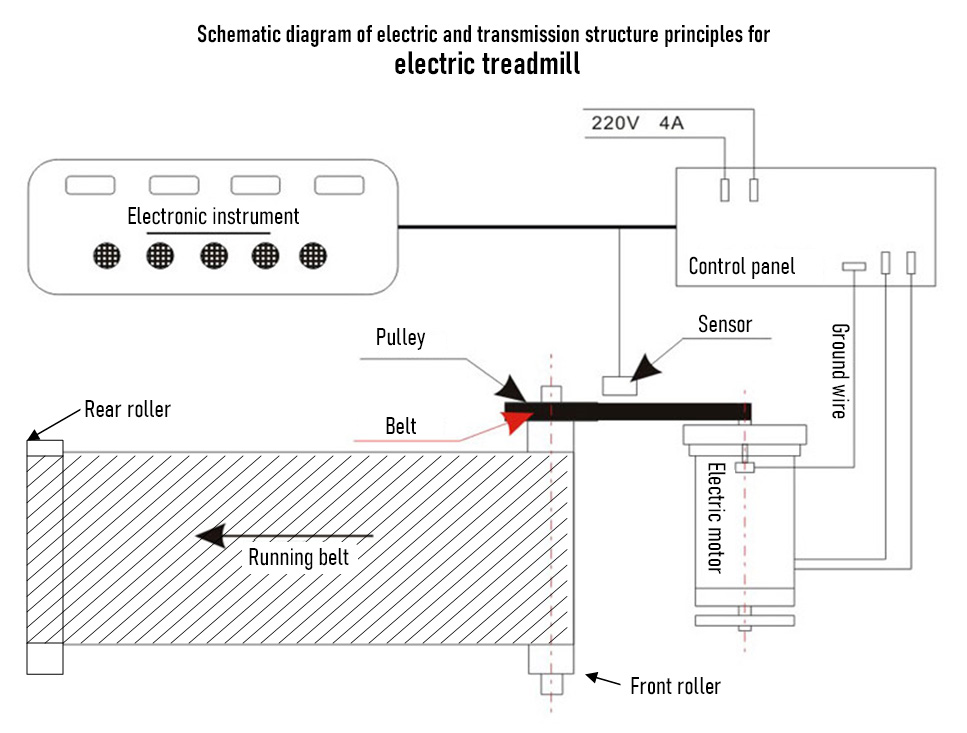

The causes of running belt sliding

Usually running machine skid or sliding phenomenon results from two areas: running belt and multi-groove belt

Cause A (running belt looseness) :

The running belt was not set well during the production at treadmill factory, or it was loosen causing plastic deformation after long time use, resulting in reduced friction between running belt and roller.

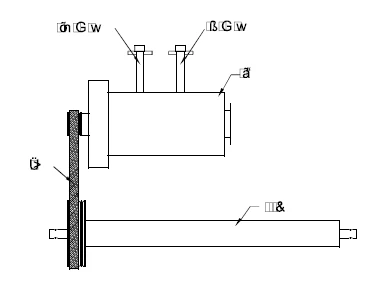

Cause B (multi-groove belt looseness) :

The multi-groove belt connecting the motor and the roller is not set well before leaving the factory, or relaxed after a long time of use, resulting in insufficient tension, or too much lubricating oil under the running belt was thrown onto the inside of multi-groove belt , resulting in insufficient friction of the multi-groove belt.

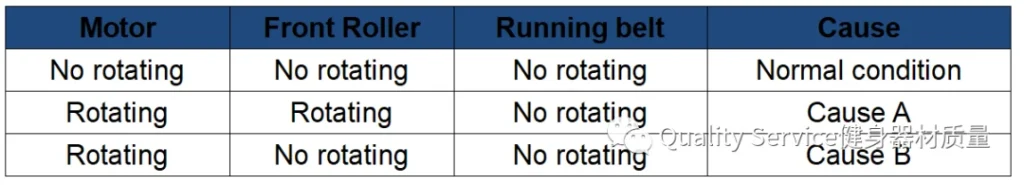

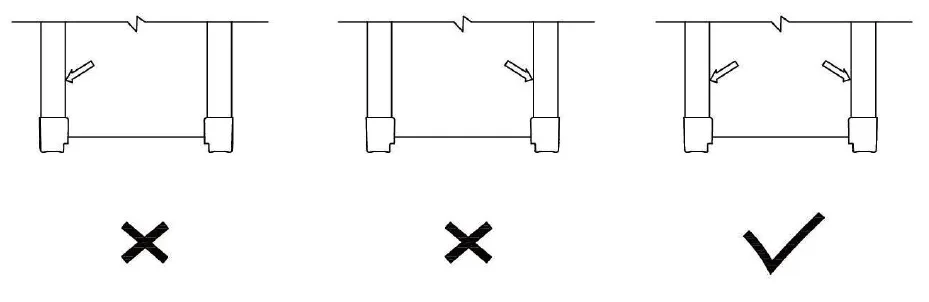

Running belt or multi-groove belt problem?

So how to know which part was wrong? Please follow the instruction below:

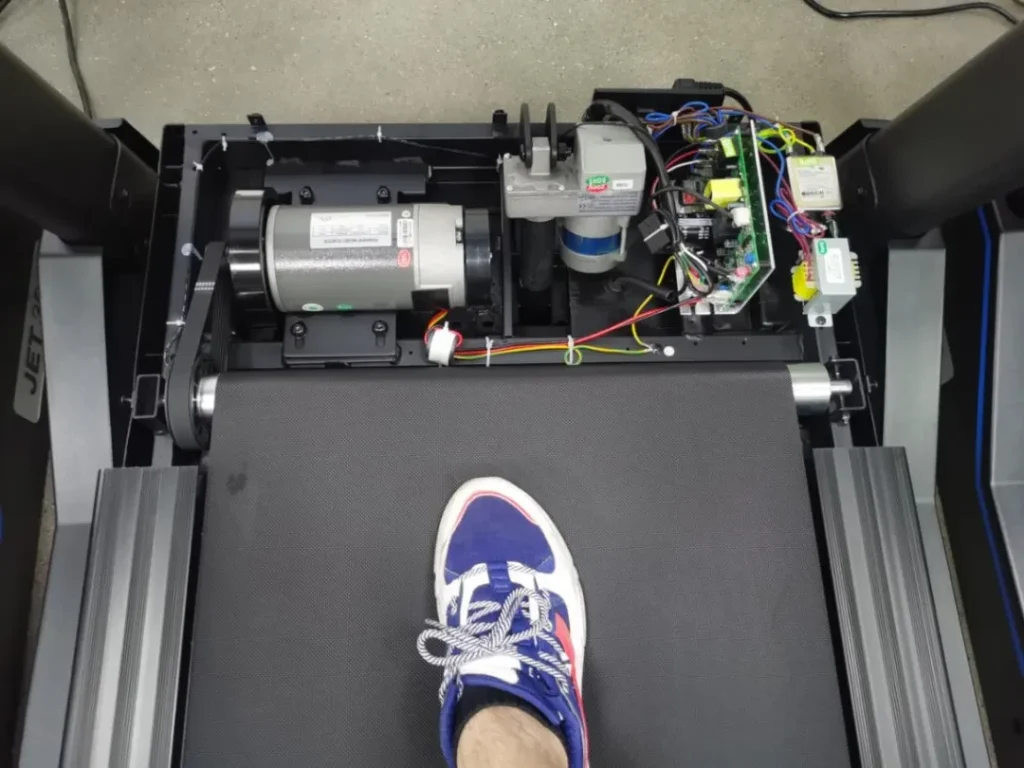

Remove the motor cover of the treadmill first, start the treadmill. Right after the running belt is moving, you should use your feet to stop the running belt moving as much as your can while your hands have to grasp with the handrail hardly in order to keep your body balanced. By doing that, the running belt is possibly stopped moving, then you could observe the following situation, and make the judgment.

Notes:

If the treadmill running belt skid is not severe (that is, close to the normal condition mentioned above), the following conditions may occur. As a maintenance personnel, you need to understand the configuration of the treadmill before operation.

- Some low-end treadmills may not include current overload protection mechanism, trying to stop the movement of belt after starting treadmill may cause burning the motor

- A treadmill that has a higher current value may be very hard to be stopped by inexperienced users.

Action to sliding problem

After determining cause A or cause B according to the above operation, we should take corresponding countermeasures.

Countermeasure to cause A:

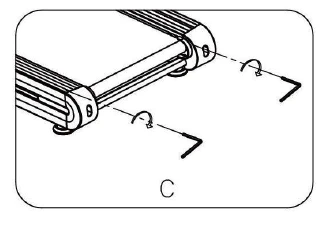

Unplug the safety lock (stop the machine) and turn the adjusting bolts on the left and right side respectively with 1/4 turn clockwise by using the inner hexagon wrench. Then insert the safety lock, start the treadmill and stand on the belt to check whether the sliding phenomenon still exists. Repeat the steps until the belt gains the right tension.

After the adjustment of tension of running belt is completed, you also need to make sure the running belt is centered. You could set the treadmill speed at 6-8km /h, running a few minutes, then to check. If it is not centered, use the inner six wrench to fine-tune one side (refer to the manual operation guide for details), until it goes the centered.

Notes:

- To adjust the tension of running belt, you just make maximum of a quarter circle each time. If the running belt is too tight, it will harm the life of the transmission system parts.

- If you are a professional technician , you can adjust the running belt without stopping the machine. Non-professional personnel needs to operate under the guidance of professional technician.

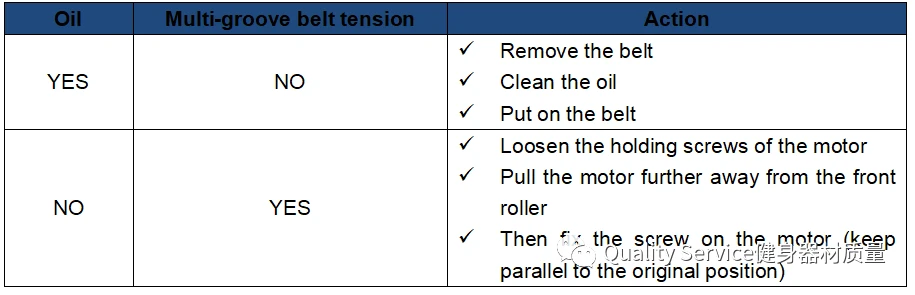

Countermeasure to cause B:

You should firstly check whether oil inside in multi-groove belt and the tension of multi-groove is adequate, then take action accordingly.

Notes:

- Check the belt tension by using a tension meter if available (normally the belt tension should be 40~60NW/ groove).

- When loading and unloading a belt, you have to switch off the power instead of operating while the motor is running, which is very dangerous!

- After adjustment, you should step on the running belt again at the speed of 8~10KM/H to check whether the belt slides.

Comments (0)

No comments yet, be the first to comment!